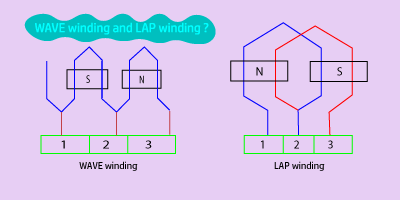

A rotating machine has an essential part known as Armature winding. Generally, this is responsible for making a rotating magnetic field in a machine. As a result, it provides back emf to the supply. This armature winding is classified into two types. One is Lap winding and another is Wave winding.

These have their special advantages to use. Coils of the armature winding are connected to the commutator in either wave winding or lap winding form, in the DC machine. These are the only arrangements for the winding.

Table of Contents

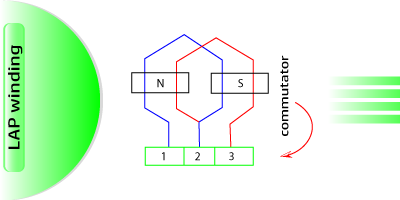

Lap winding Definition

A Lap winding is defined as a type of winding, with the total number of paths equal to the number of poles.

According to LAP winding, the ends of the armature coils of the DC machine connect to the adjacent commutator segments. Such that the total number of parallel paths made by the winding is equal to the number of poles formed. That is, A=P.

Note: You may remember this by the terms in “L A P” (A=P).

Equalizer ring use in Lap winding

- An Equalizer ring is a coil that connects only lap winding.

- Under practical conditions, there is a discontinuous air gap that produces an unbalance in the generated EMF.

- As seen in practice, coils under stronger poles have larger EMF whereas conductors under the weaker poles produce imbalance.

- As a result, some brushes carry currents more than the rated limits and some contain lesser.

- Thus current cannot reverse in the commutation time as the brushes are overloaded which makes SPARK on the surface of the commutator or the brushes.

- So we use an Equalizer ring to eliminate this hazard.

- It is a thick conductor of copper that connects the main armature winding which has a potential difference between them.

- As there exists potential difference, the excessive current flows through the Equalizer ring rather than coils. This prevents sparks on the brushes.

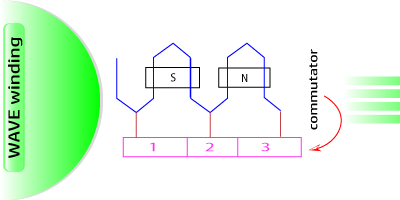

Wave winding Definition

According to wave winding, each of the armature coils connects to the commutator segments skipping some segments in between. So that there are only two parallel paths between the +ve and -ve commutator poles. That is, A=2 always.

Dummy coils are used in Wave winding

Dummy coils are used to provide mechanical balance to the rotor. Dummy coils are used in wave winding only, for increasing mechanical balance.

- A wave winding has a specific number of coils needed for the given number of slots.

- But sometimes armature slots in the armature winding do not meet that requirement. This means available slots are either more than or less than the coils.

- Some slots are left blank without having any coils in them. This is a blunder mistake. Because any slot cannot be empty in the armature winding, it gives a MECHANICAL imbalance.

- So we use dummy coils in the empty armature winding slots.

- The Dummy coils are inserted to simply provide MECHANICAL balance. They do not connect to the armature winding electrically.

Difference between LAP and WAVE winding

So here are some main differences between the LAP and WAVE winding.

| S.No. | LAP winding | WAVE winding |

| 1 | Lap winding has the coil that laps back to the previous coil. | Whereas in Wave winding it proceeds forward without overlapping the previous coil. |

| 2 | Dummy coils are used as an additional coils. | But in this, the previous and succeeding coils connect some distance apart. |

| 3 | In Lap winding, the previous and succeeding coil connects to the commutator adjacently. | In contrast, there are only two parallel paths. |

| 4 | With more number of parallel paths, it has lesser generated EMF. | It has more EMF generated as it has only two parallel paths. |

| 5 | An equalizer ring is used as an additional coil. | Dummy coils are used as additional coils. |

| 6 | Less efficient. | More efficient. |

| 7 | Gives a High current but low voltage as output. | Gives Low current but High voltage as output. |

Application of Lap and Wave winding

In general, Lap winding fabricates low-voltage, High-currents machines. And Wave winding produces High-voltage, low-current machines.